In the long history of Chinese culture, the gold and silver thread craft shines with its unique brilliance. This ancient technique can be traced back to the Han Dynasty, when people began to try to embed metal filaments into fabrics or other materials to create breathtaking works. With the passage of time, gold and silver thread gradually became one of the exclusive symbols of luxury for the royal nobility, and was widely used in royal costumes, palace buildings and other precious artifacts.

Nowadays, this exquisite craftsmanship that has been passed down for thousands of years is no longer an unattainable existence, but is integrated into all aspects of modern social life, showing endless vitality and creativity. Whether it is a haute couture dress in the fashion world or a small decoration in the home decoration, you can see the shining golden lines flowing in it.

When we look at real life, we will find that the figure of gold and silver thread is almost everywhere. They are cleverly hidden in the various works carefully created by designers, giving each item a unique soul and value.

For example, the common dragon and phoenix gown skirt on wedding occasions is one of the typical representative works. This kind of Chinese wedding clothing usually uses a large number of gold and silver thread patterns embroidered by hand as the main elements, implying good luck, wealth and glory; and on the lobby background wall of some high-end restaurants or hotels, you can often see The huge relief murals made by artists using new materials combined with traditional techniques show a dreamy effect with the help of light and shadow changes, which makes people linger.

How on earth did such an exquisite work of art come into being? In fact, there are a series of extremely complicated production steps behind it. First of all, you need to select high-quality gold and silver raw materials, after smelting and stretching to form a very fine single fibrous material for standby. Then it enters the most critical stage of embroidery. Experienced craftsmen will patiently outline the outline one by one according to the pre-drawn drawings and fill the main part of the picture with distinct colors until the whole cloth is completely covered.

of course, in order to ensure that every detail finally delivered to the customer is flawless, the quality inspection personnel will also track and supervise the implementation of each link throughout the process and randomly sample and test whether many indicators such as wear resistance strength are qualified or not in order to allow the ex-factory sales and circulation market for the vast number of consumers to freely purchase, collect and use, and have endless fun.

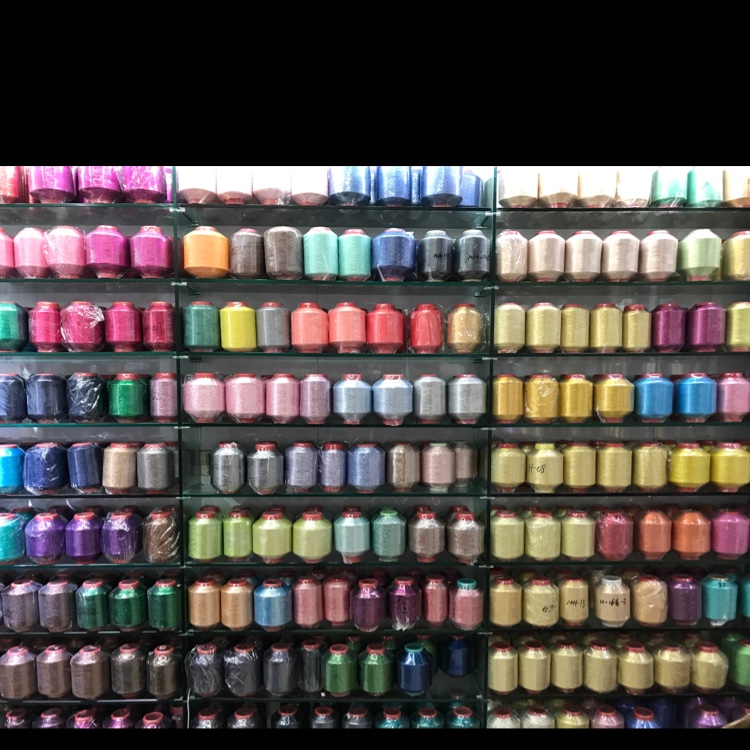

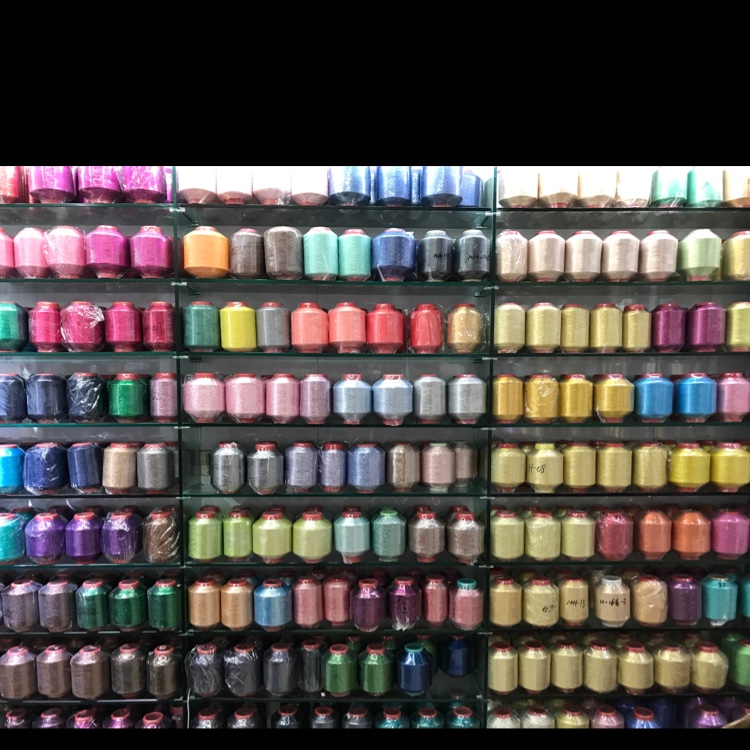

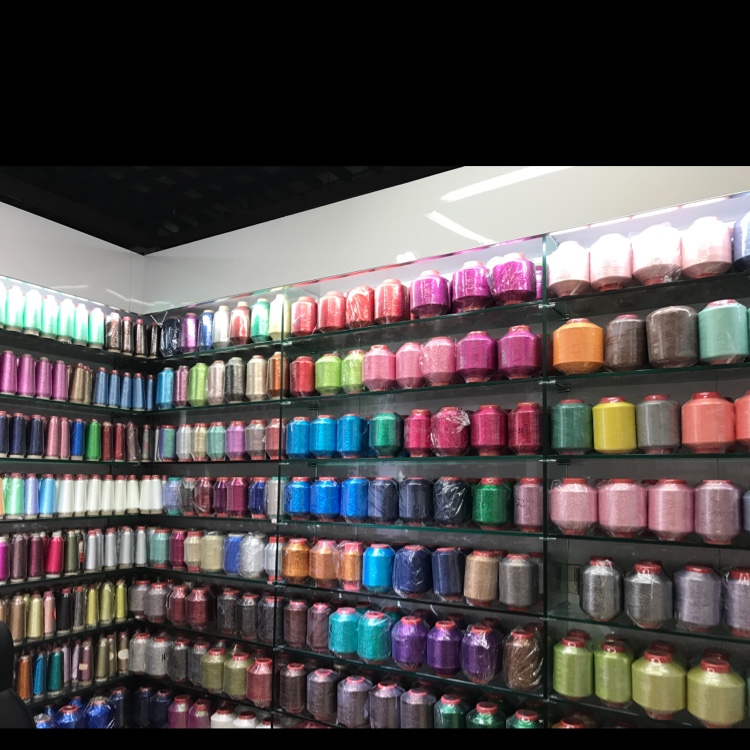

in the face of a dazzling array of market shelves on the display rack of the many options, how can we accurately determine which one is the real high quality? here to share with you a few simple but very important screening rules:

first of all, we should carefully look at whether the appearance is smooth and there is no residual phenomenon of concave and convex marks. Secondly, the texture should be soft and moderate when touched by hand, but it should be hard and stiff, not loose and messy, and lack of support. Finally, don't forget to check whether there are obvious problems such as degumming and cracking on the back! As long as you check and confirm the clearance one by one in strict accordance with the above requirements, you can basically take it home and enjoy it ~